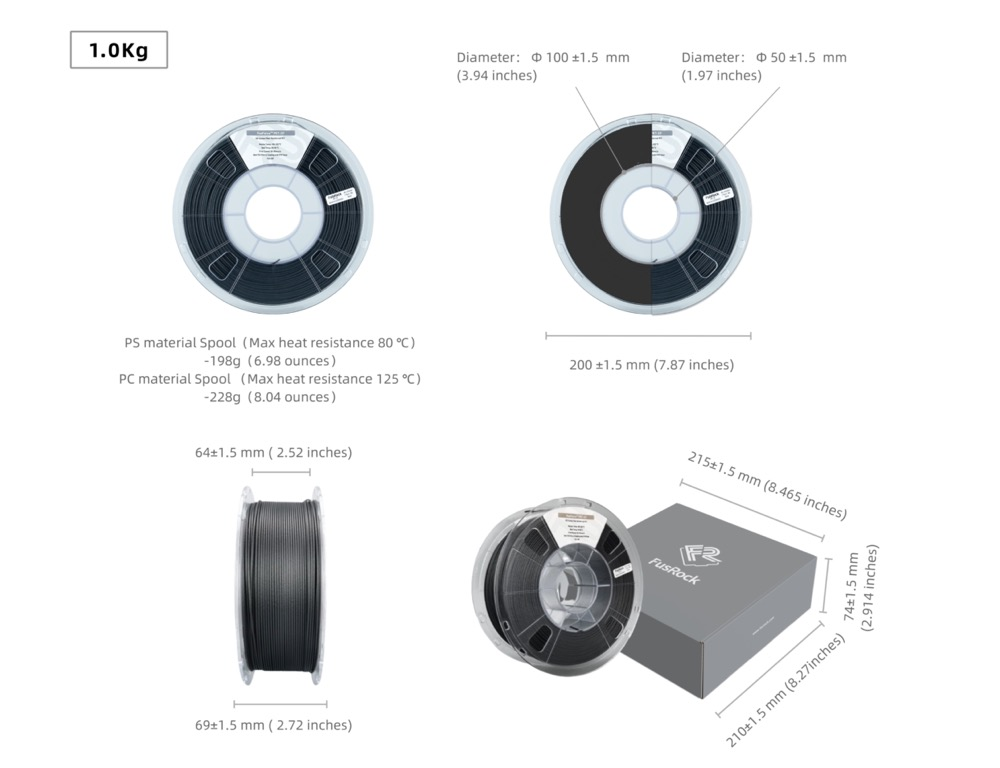

Net weight

1 Kg / 2.5Kg / 3Kg

Dlameter

1.75 mm / 2.85 mm

Color

White / Black / Gery / Red / Green / Army Green / Yellow / Blue / Purple / Orange

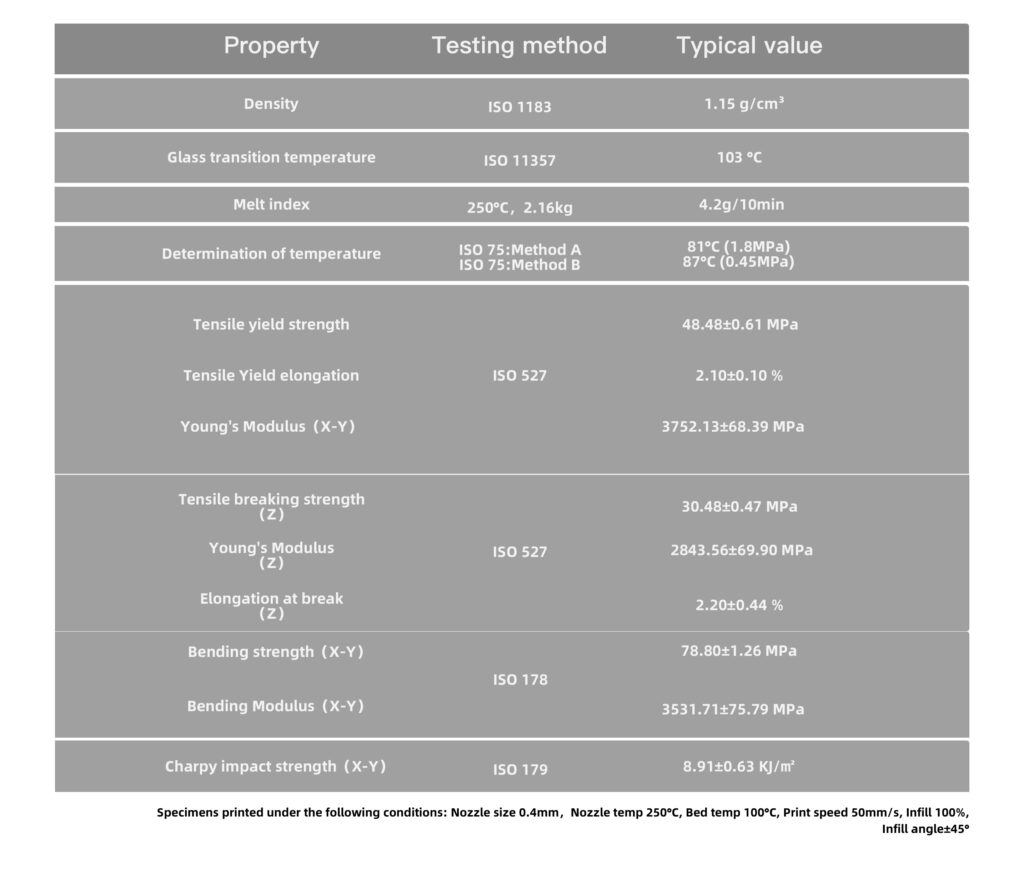

Technical Data Sheet

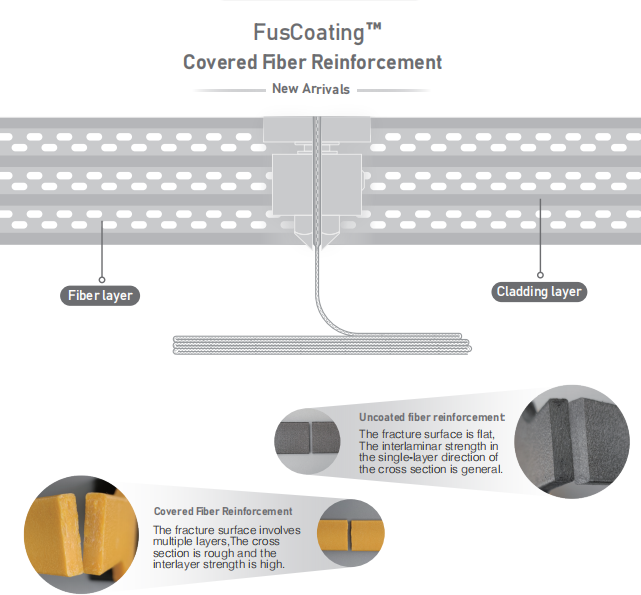

FusCoating™️ NexABS-GF25 is one type 3D printing ABS filament with co-extrusion skin-core structure and 25% glass fiber to improve its mechanical properties.

Product Description

FusCoating NexABS-GF25 is one type 3D printing ABS filament with co-extrusion skin-core structure and 25% glass fiber to improve its mechanical properties.

Previous slide

Next slide

Material Properties

Recommended printing conditions

Nozzle Temperature | 250-270°C |

Recommended Nozzle Diameter | 0.4-1.0 mm |

Recommended build surface treatment | PEI or Coating with PVP glue |

Build plate temperature | 100-110°C |

Chamber Temp | Sealing or 40-70°C |

Cooling fan speed | 0-20% |

Print speed | 30-120 mm/s |

Retraction distance | 1-3 mm |

Retraction speed | 1800-3600 mm/min |

Recommended Support Material | FusFree™ S-Multi Quick-Remove Support |

Drying setting | 70℃ for 4-6h |

Annealing | N/A |

Printing Tips:

- FusCoating™ NexABS-GF25 has a higher fiber content compared with ordinary ABS-GF. This technology further improves the warping resistance and rigidity of ABS materials, so the chamber temperature can be properly reduced to achieve energy saving.

- If the filament has been opened for a long time and problems such as air bubbles and stringing appear during the printing process, please dry the filament at 70°C for 4-6 hours.

- It is recommended to place the printer in a well-ventilated environment when printing with ABS material.

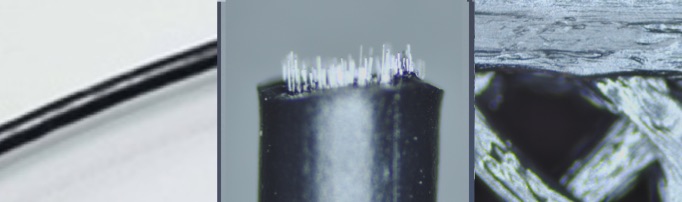

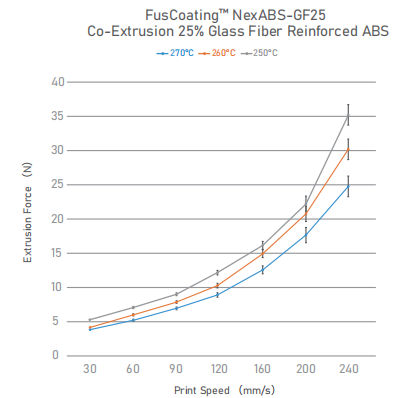

- FusCoating™ NexABS-GF25 can maintain a core-skin structure when extruded from the nozzle. It is based on the mechanism that the melt polymer is in a laminar state when it flows stably, However,when the printing speed is too high, the melt flow state will become unstable, and the filaments extruded from the nozzle will no longer have the skin-core structure anymore, which can cause the rough surface of the printed part. When this phenomenon occurs, it is recommended to increase the printing temperature or reduce the extrusion speed.

- It is recommended to use Phaetus hardened steel nozzles or nozzles with greater abrasion resistance,which can effectively improve the printing quality. The thickness of the heating block is recommended to be no less than 12mm.

Extrusion Force vs Print Speed Test

Test parameters: 12mm length brass heat block, BMG extruder, Phaetus Hardened Steel Nozzle, Nozzle size 0.4mm, Layer Height 0.2mm.