ABS-ESD is an ESD-safe filament based on multiwalled carbon nanotube -filled ABS

Product Description

FusForce™ ABS-ESD is an ESD-safe filament based on multiwalled carbon nanotube -filled ABS. Thanks to its excellent printability and electrostatic dissipative properties, ABS-ESD is ideal for general manufacturing and electronic industry.The main raw material of FusForceTM ABS-ESD is an ABS resin synthesized by continuous bulk polymerization technique. Thanks to this advanced production process, the residual amount of solvents and monomers used in the production process in the final ABS product is so low that the filament has a low odor during printing.

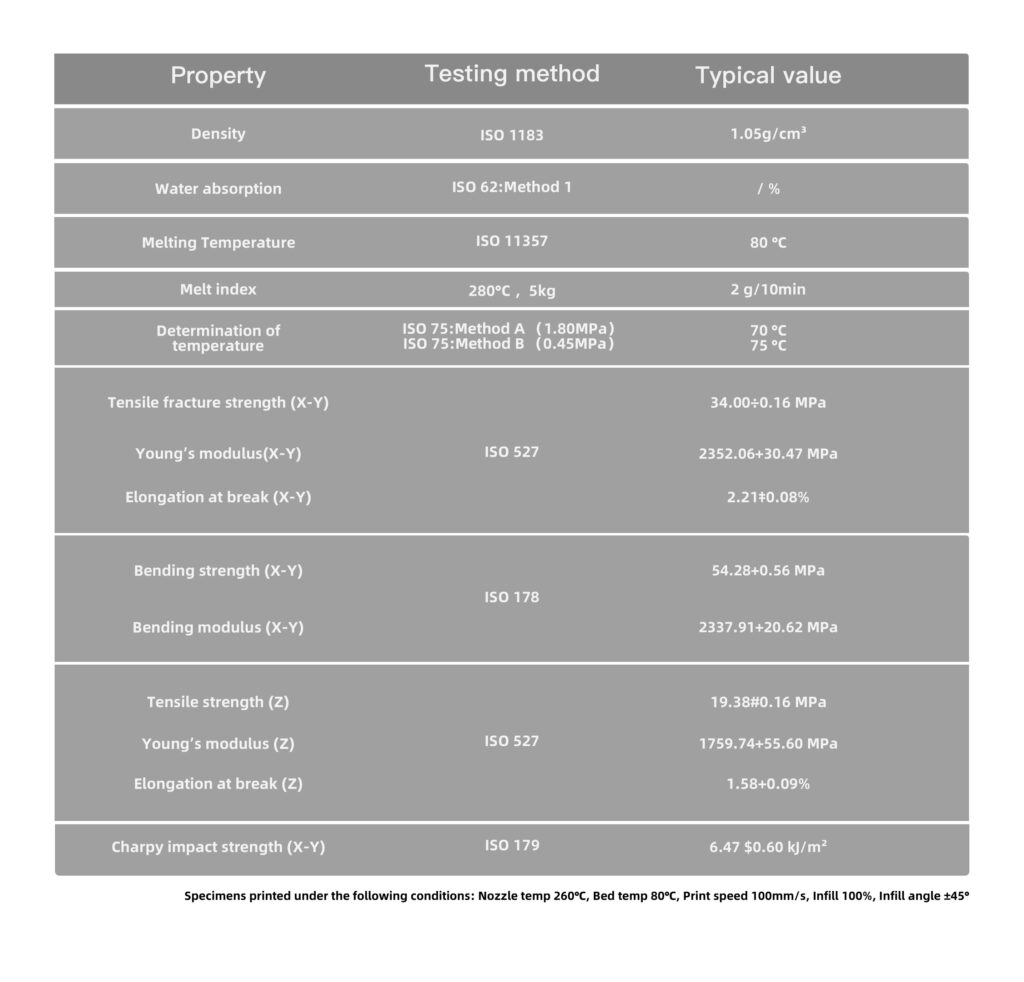

Material Properties

Recommended printing conditions

Nozzle Temperature | 250-270 °C |

Recommended Nozzle Diameter | ≥0.2 mm |

Recommended build surface treatment | PEI or Coating with PVP glue |

Build plate temperature | 80-90 °C |

Chamber Temp | Sealing or 40-70°C |

Cooling fan speed | 0-30 % |

Print speed | 30-150 mm/s |

Retraction distance | 1-5 mm |

Retraction speed | 1800-3600 mm/min |

Drying setting | 70℃ for 4-6h |

Annealing | N/A |

Printing Tips:

1. Compared with PLA, PETG and other materials, ABS materials need a higher chamber temperature to help release the residual stress during the printing process. Please keep the printer chamber closed during the printing process. It can effectively avoid printed parts from warping and cracking. If the device has a heated chamber, it is recommended to set the temperature of heated chamber between 40-60°C.

2. If the ABS-ESD filament has been unpacked for a long time and the printing quality starts to degrade during the printing process, please dry the filament at 70-80°C for 4-6 hours before printing.

3. Although ABS-ESD has much less odor compared with similar products, it is still recommended to place the printer in a well-ventilated area during printing.