High-speed Printing ABS

Product Description

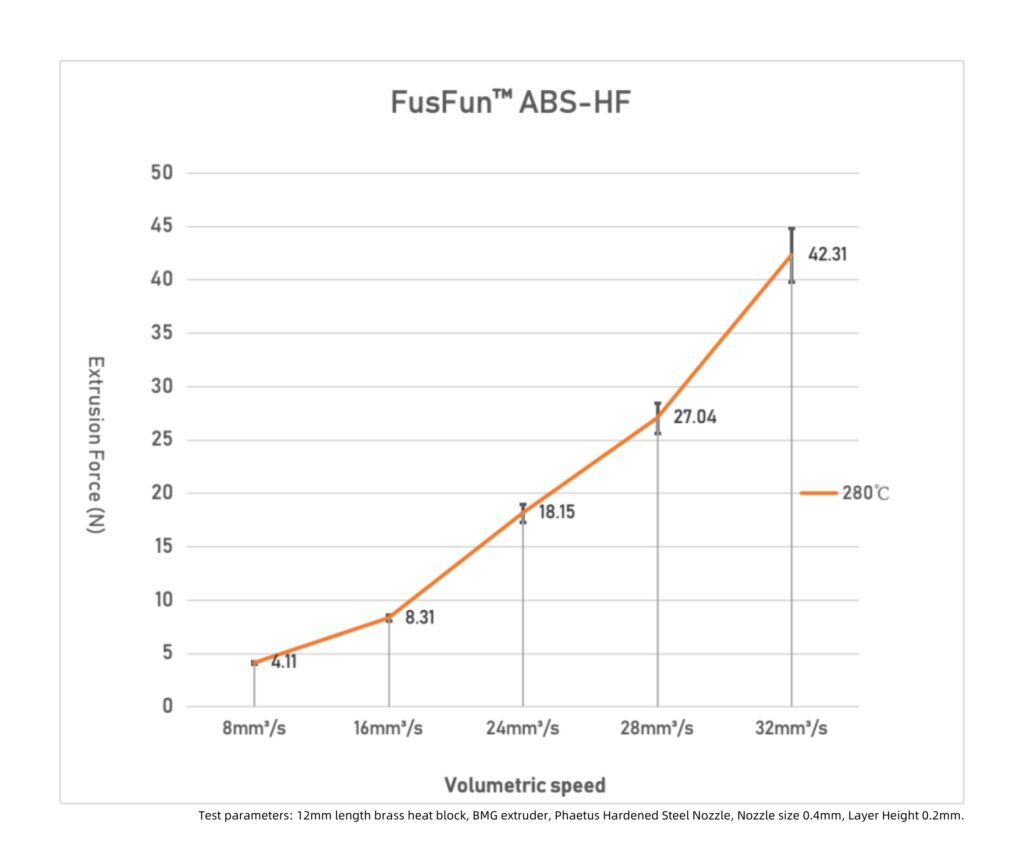

FusFun™ ABS-HF is a high-flow modified ABS filament that supports high-speed printing. The maximum practical extrusion flow rate can reach 28mm³/s*. Compared with ordinary ABS materials, it releases less odor when printing and has better warpage resistance. And anti-cracking ability, and excellent impact resistance.(*For details on extrusion hardware configuration, see Extrusion Traffic Test)

Material Properties

Property | Testing method | Typical value |

Density | ISO 1183 | 1.05 g/cm³ |

Glass transition temperature | ISO 11357 | 80°C |

Melt index | 250℃,2.16kg | 13 g/10min |

Determination of temperature | ISO 75:Method A ISO 75:Method B | 65°C (1.8MPa) 72°C (0.45MPa) |

Tensile yield strength | ISO 527 | 37.13±0.59 MPa |

Tensile Yield elongation | 2.32±0.07 % | |

Young’s Modulus | 2115.10±24.02 MPa | |

Tensile breaking strength | 30.29±2.28 MPa | |

Elongation at break | 3.65±1.52 % | |

Tensile breaking strength | ISO 527 | 33.48±0.23 MPa |

Young’s Modulus | 2097.03±37.77 MPa | |

Elongation at break | 4.07±0.57 % | |

Bending strength | ISO 178 | 57.46±0.25 MPa |

Bending Modulus | 2117.02±32.46 MPa | |

Charpy impact strength | ISO 179 | 23.16±2.32 KJ/㎡ |

Specimens printed under the following conditions: Nozzle size 0.4mm,Nozzle temp 250°C, Bed temp 80°C, Print speed 50mm/s, Infill 100%, Infill angle ±45°

Recommended printing conditions

Nozzle Temperature | 230-250°C |

Recommended Nozzle Diameter | ≥0.2 mm |

Recommended build surface treatment | Glass、PEI Film or PC Film |

Build plate temperature | 70-80°C |

Chamber Temp | Sealing or 60-80°C |

Cooling fan speed | 0-50% |

Print speed | 30-200 mm/s |

Retraction distance | 1-3 mm |

Retraction speed | 1800-3600 mm/min |

Recommended Support Material | FusFree™ S-Multi Quick-Remove Support |

Drying setting | 70℃ for 5-6h |

Annealing | N/A |

Printing Tips:

1.If the ABS-HF filament has been unpacked for a long time and the printing quality starts to degrade during the printing process, please dry the filament at 70°C for 4-6 hours before printing.

2. It is recommended to place the printer in a ventilated environment when printing.

Extrusion Force vs Print Volumetric Speed Test