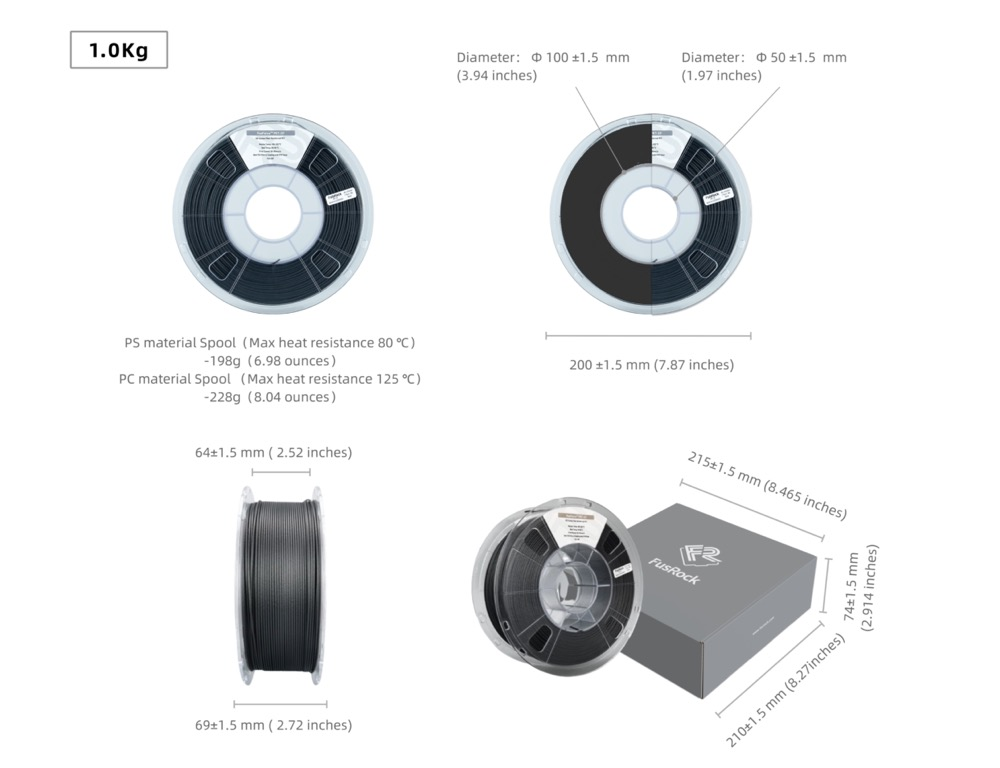

Net weight

Dlameter

Color

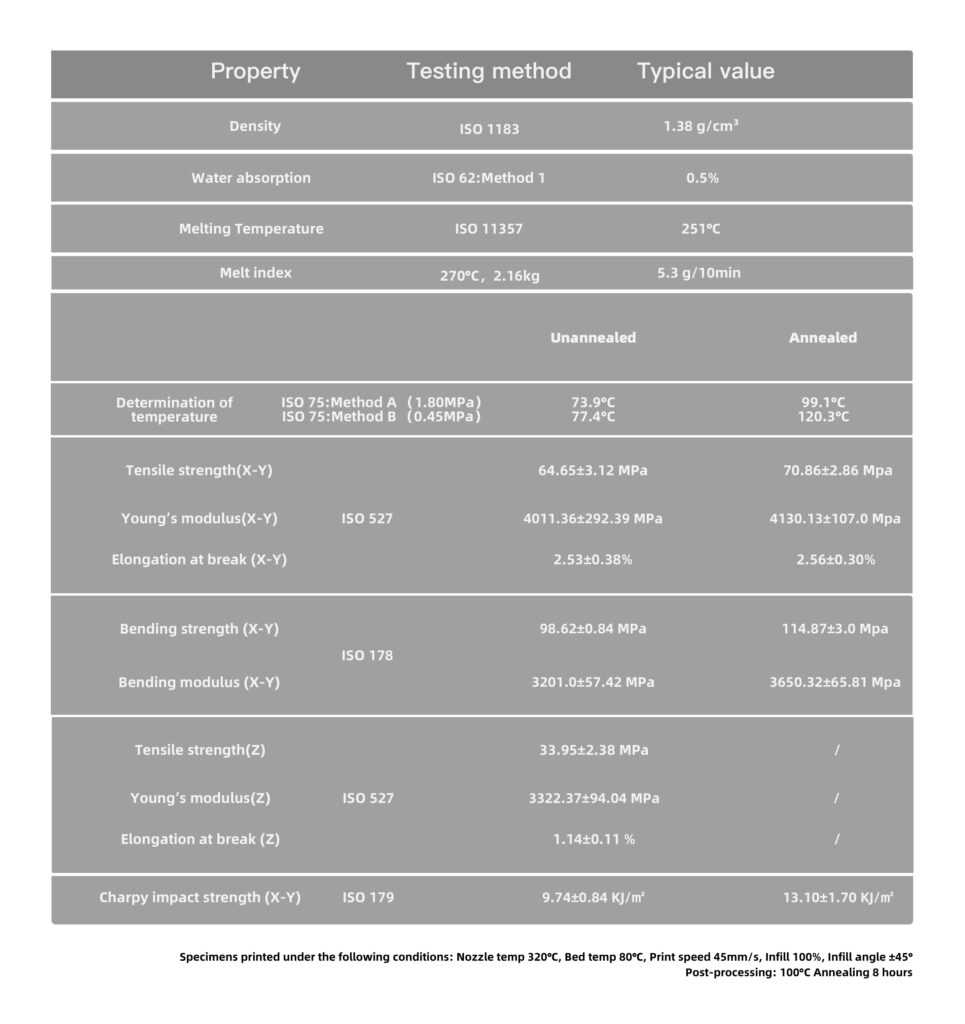

Technical Data Sheet

15% chopped Glass fiber reinforced Polyethylene Terephthalate FDM material.

Product Description

Material Properties

Recommended printing conditions

Nozzle Temperature | 280–320 °C |

Recommended Nozzle Diameter | 0.4-1.0 mm |

Recommended build surface treatment | PEI or Coating with PVP glue |

Build plate temperature | 60-80 °C |

Chamber Temp | Supports printing without sealing |

Cooling fan speed | Off |

Print speed | 30-120 mm/s |

Retraction distance | 1-3 mm |

Retraction speed | 1800-3600 mm/min |

Recommended Support Material | FusFree™ S-Multi Quick-Remove Support |

Drying setting | 100-120℃ for 4-6h |

Annealing | 80-100℃ for 4-8h |

Printing Tips:

1.Although the moisture absorption of PET material is very low, it is very sensitive to moisture. Printing after absorbing moisture will result in ozzing, extruding with bubbles and rough surface appearance, thus reducing print quality. It is recommended that put the filament into a dry box (humidity below 15%) immediately after opening the FusForce™️ PET-GF vacuum foil bag for printing. Please put the unused filament back into the original aluminum foil bag for sealed storage.

2.After the material is damp, there will be more printing ozzing, bubbles extruded and rough printing surface. Please dry the filament in an oven at 100-120℃ for 4-6h to restore the printing quality of FusForceTM PET-GF.

3.Phaetus hardened steel and above grade nozzles shall be selected, which can effectively improve the print quality. Besides, it is recommended that the thickness of the heating block should no less than 12mm.

After the printing, the printed part can be annealed to further improve the strength of FusForceTM PET-GF print part. Annealing conditions: place the printed part at 80-100℃ for 4-8 hours and cool to room temperature naturally.

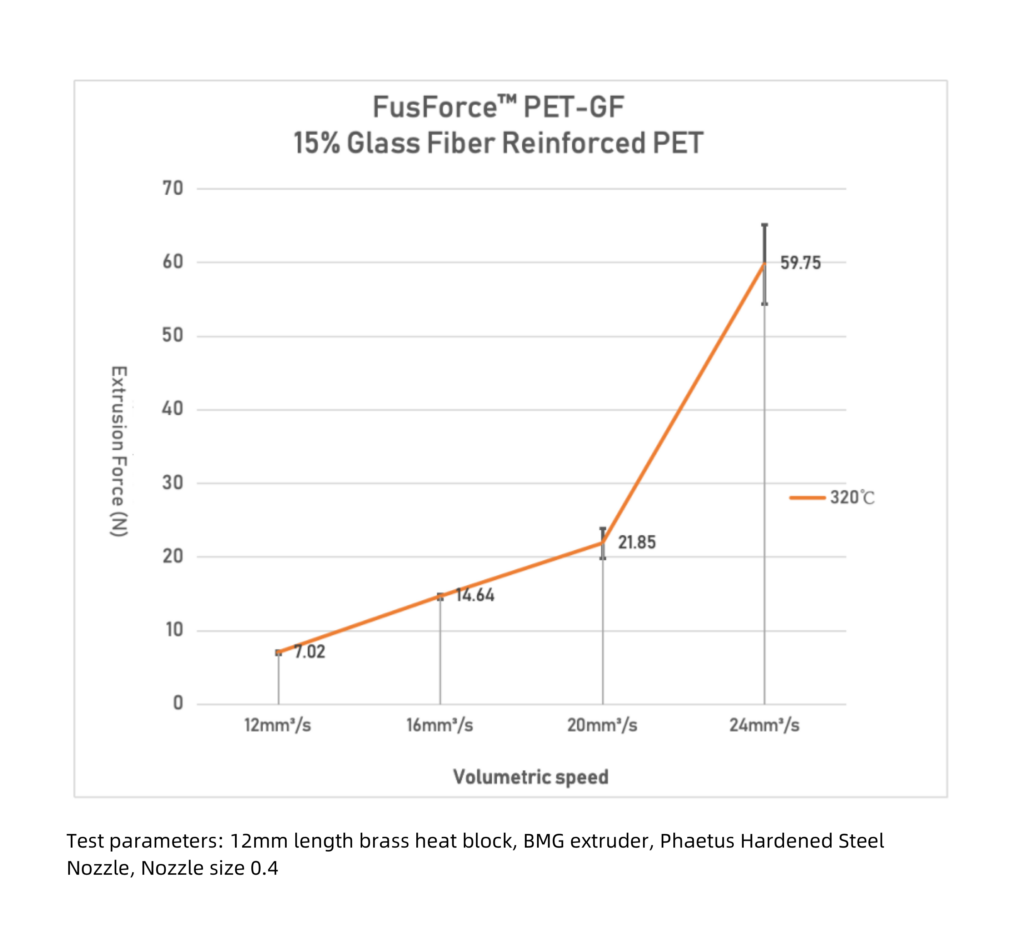

Extrusion Force vs Print Volumetric Speed Test