Lightweight ASA 3D Printing Material

Product Description

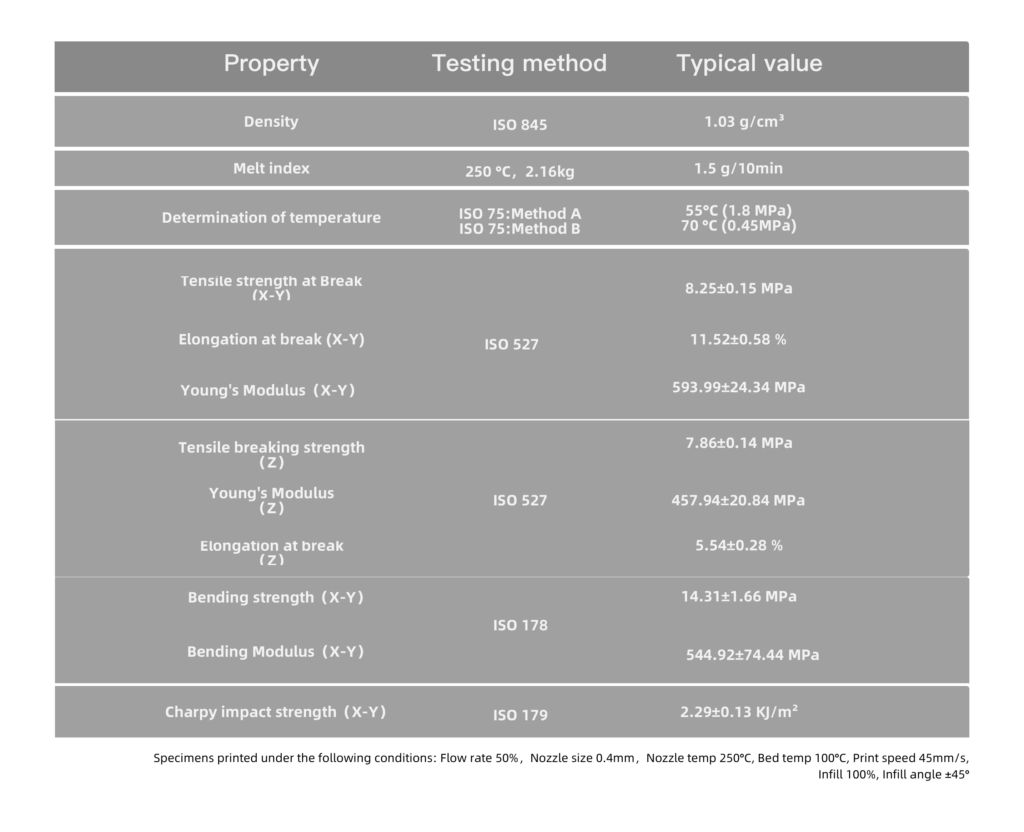

Material Properties

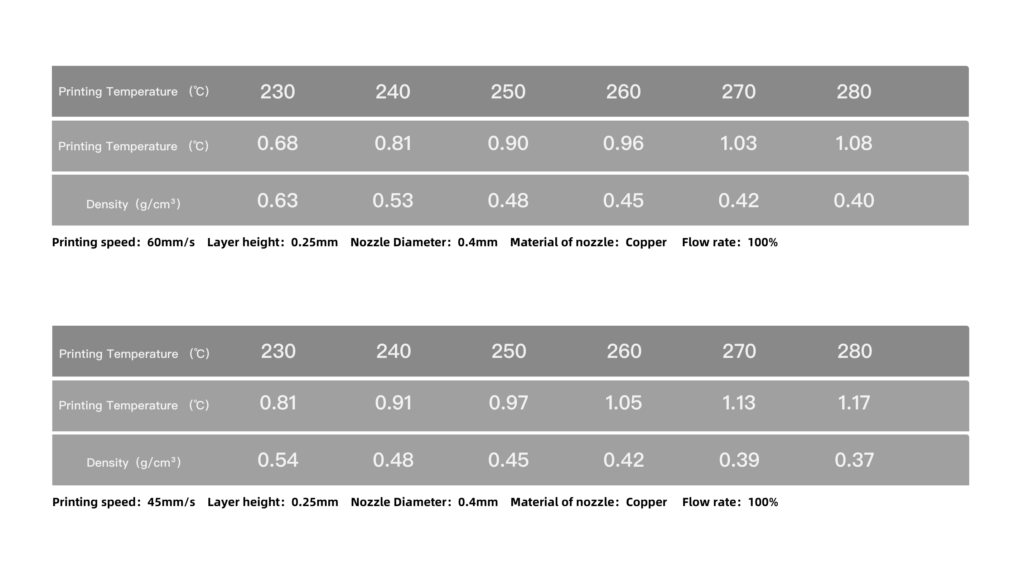

ASA-Aero LT effect of printing temperature on foaming

Recommended printing conditions

Nozzle Temperature | 240-280°C |

Recommended Nozzle Diameter | ≥0.4 mm |

Recommended build surface treatment | Glass、PEI Film or PC Film |

Build plate temperature | 80-110°C |

Chamber Temp | Sealing or 40-70°C |

Cooling fan speed | 0-50% |

Print speed | 30-90 mm/s |

Retraction distance | off |

Retraction speed | off |

Recommended Support Material | N/A |

Drying setting | 60℃ for 4-5h |

Annealing | N/A |

Printing Tips:

1.Since ASA-Aero adops the ‘on-demand foaming’ technology, the filament will continue to expand in the nozzle after being heated during the printing process. Therefore, it will cause unavoidable stringing during the nozzle movement. Even adjusting the retraction setting in the slicing software cannot solve this problem. Based on the above, it is recommended to turn off the retraction setting.

2.Because ASA materials have a high glass transition temperature, a certain ambient temperature(40-70°C) is required during printing to release the internal stress of the printed parts and reduce warping. When printing thin-walled models without any form of insulation, it is recommended to use nozzles with a diameter of 0.6mm or more to ensure the strength of printed parts and reduce shrinkage.

3.When printing with ASA-Aero filaments, please place the enclosed printer in a ventilated environment.