A high toughness and 78D shore hardness flexible 3D printing material

Product Description

TPU78D is a semi-rigid 3D printing material that ensures a certain degree of flexibility while also taking into account good rigidity. TPU78D has excellent impact resistance and wear resistance, and also has high heat resistance. TPU78D is easy to print, compatible with most extruders, and does not even need to turn on the base plate heating. It can be used in the production of parts that replace ABS and have high impact requirements.

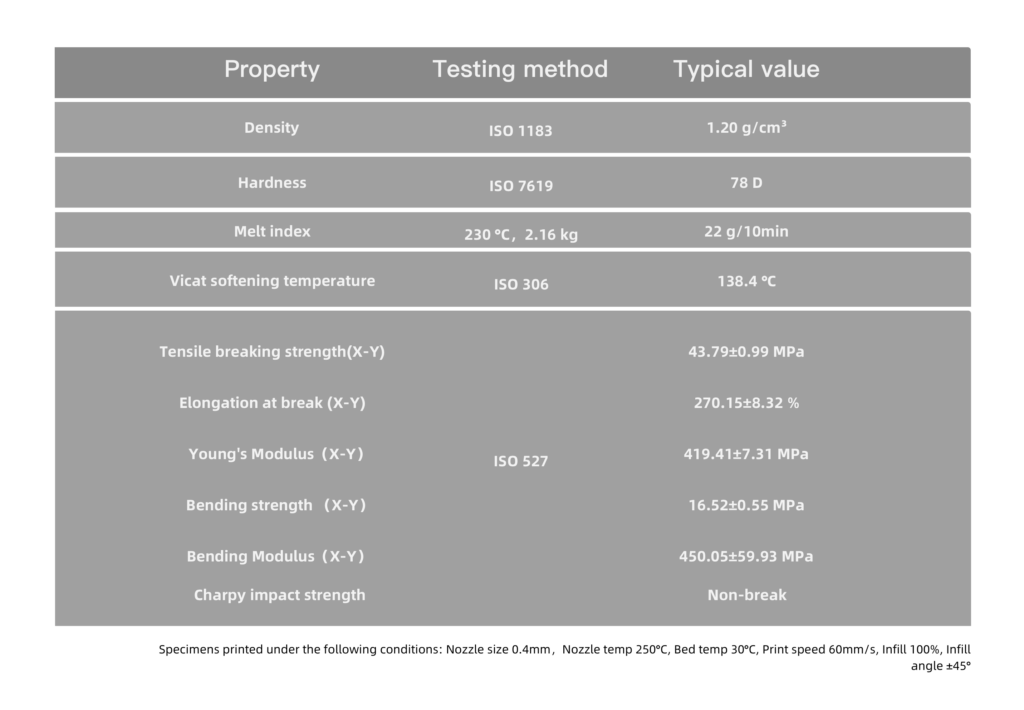

Material Properties

Recommended printing conditions

Nozzle Temperature | 240-270 °C |

Recommended Nozzle Diameter | ≥0.2mm |

Recommended build surface treatment | PEI or Coating with PVP glue |

Build plate temperature | 20-90 °C |

Chamber Temp | N/A |

Cooling fan speed | Off |

Print speed | 30-120 mm/s |

Retraction distance | 1-5 mm |

Retraction speed | 1800-3600 mm/min |

Recommended Support Material | FusFree™ S-Multi Quick-Remove Support |

Drying setting | 70-80℃ for 4-6h |

Annealing | N/A |

Printing Tips:

If you want to achieve high-speed printing, it is recommended to use direct extruders, such as BMG extruder, Titan extruder and Hemera extruder, and appropriately increase the nozzle temperature.

TPU material is very easy to absorb moisture when exposed to air, and printing after absorbing moisture will result ozzing, extruding with bubbles and rough surface appearance, thus reducing print quality. It is recommended that put the filament into a dry box (humidity below 15%) immediately after opening the FusFlex™ TPU78D vacuum foil bag for printing. Please put the unused filament back into the original aluminum foil bag for sealed storage.

After the material is damp, there will be more printing ozzing, bubbles extruded and rough printing surface. Please dry the filament in an oven at 70-80°C for 4-6h to restore the printing quality of FusFlex™ TPU78D.